Hardness Test Blocks & Machines

Hardness

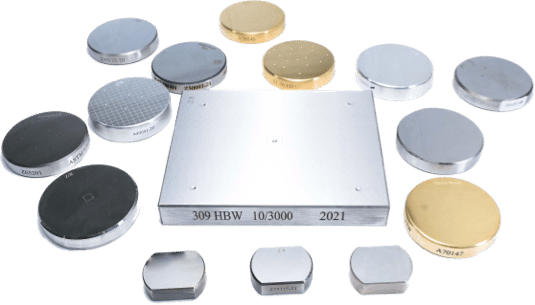

Test Blocks

Hardness test blocks, also known as reference blocks, are used for indirect calibration procedures and for periodic daily checks of hardness testing instruments.

View Products

Hardness

Testing Machines

Hardness testing machines are used to determine the hardness of materials, which is a measure of a material’s resistance to indentation or deformation.

View Products